Pre-Compliance EMC Testing saves Time and Money!

Pre-Compliance EMC Testing saves Time and Money! All electronic devices must pass testing by an accredited EMC testing lab. It is estimated that up to 50% of products fail final testing on their first try! Multiple trips for testing really increase the product development cost. Pre-Compliance Testing during development at your facility can prepare your device for the “Final”! This early testing helps to detect and address problems stepwise during development. Testing and correcting early avoids expensive “back tracking” to fix multiple problems. It is harder to specifically identify problems late in development. This strategy helps to save time and money during development.

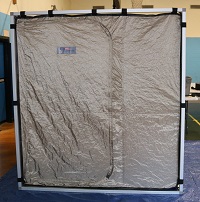

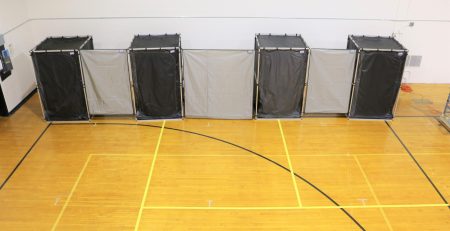

Pre-Compliance EMC Testing saves Time and Money! Perform some of your own Pre-Compliance testing at your site. You will be able to find and fix problems before Final Testing! A portable RF Shielded Testing Enclosure provides an ideal low-ambient testing environment. These enclosures can be easily deployed for EMC testing. When testing is completed, they can be stored, saving precious space. VTT is the world leader in soft sided RF Shielded EMC Testing enclosures. The specifications of the enclosures, including size, Shielding Effectiveness (SE) and options are tailored to the customer’s needs.

The testing itself is relatively straightforward. consisting of three parts:

- Radiated Emissions– This test determines if the device’s emissions are within the standard. This test requires a spectrum analyzer, an EMI Receiver, and EMI antenna, and E Field, H Field, and current probes.

- Conducted Immunity Testing– This test determines if the device is susceptible to radiation directly from other sources.

- Radiated Susceptibility Testing– This test determines if the device is affected by acceptable EMI and RFI. This test requires RF signal generators and radiating antennas.

Pre-Compliance EMC Testing saves Time and Money! With frequent EMC Testing during development, your device will “be well prepared” for Final EMC Compliance Testing! With this preparation, passing the Final EMC Compliance Test should be relatively straightforward. Poor EMC planning during product development will likely mean several expensive trips to the Final Testing Center. Save Time and Money by Pre-Compliance Testing of your device during development.

Please contact V Technical Textiles, Inc. for guidance on how Pre-Compliance Testing can be done at your site. VTT has years of experience in this area. We can also help solve your shielding issues using flexible lightweight conductive fabric solutions! Engineers love these conductive textiles as they have excellent Shielding Effectiveness!

V Technical Textiles, Inc.

www.vtechtextiles.com

info@vtechtextiles.com

(315)-597-1674 Phone

(315)-597-6687 fax

Experience, Research, Dedication, and Commitment

Comment (1)

[…] various “electromagnetic phenomena” that may possibly occur in its work environment. Pre-Compliance EMC Testing detects EMC difficulties during development, allowing correction in your own facility prior to […]