23Jul

08Jul

The Advantages of Reverberation Chambers!

The Advantages of Reverberation Chambers! Reverberation chambers are specialized RF Shielded enclosures, useful in testing emissions and susceptibility of electronic devices to electromagnetic interference (EMI). These chambers are crucial in ensuring that electronic devices operate correctly in environments of high levels of electromagnetic activity. Our product, the Soft Sided Vibrating Intrinsic Reverberation Chamber, represents a significant advancement in this field. Unlike traditional rigid-walled chambers, our reverberation chamber features walls made of conductive metalized textiles. ...

25Jun

Pre-Compliance EMC Testing-many Benefits!

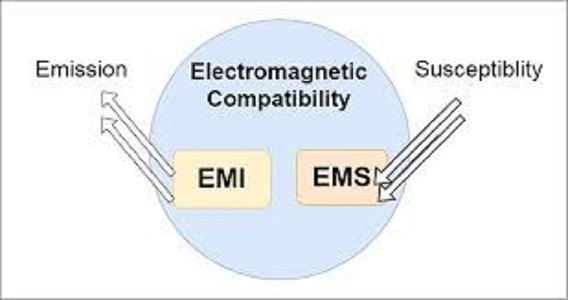

Pre-Compliance EMC Testing-many Benefits! While this testing doesn't replace the need for final compliance testing, it offers several benefits: Early Identification of Issues-Helps to identify and address EMC issues early in product development cycle, allowing for mitigation and optimization before final compliance testing. Cost savings-Correcting EMC issues before final testing is generally less expensive than correcting after a Final Compliance failure. Corrections are less expensive the earlier that they're made during product development. Faster Time-to-Market-Early detection and...

18Jun

Pre-Compliance EMC Testing-Benefits Abound!

Pre-Compliance EMC Testing-Benefits Abound! in product development, ensuring that electromagnetic compatibility (EMC) is crucial. EMC testing assesses the product's ability to function correctly without emitting harmful electromagnetic interference (EMI). without being affected by external electromagnetic fields. Incorporating Pre-Compliance EMC early and often during development can yield significant benefits, transforming potential roadblocks into opportunities for innovation and efficiency. Pre-Compliance EMC testing identifies potential EMC issues early in the development cycle. By detecting problems early, engineers...

17Jun

Innovating EMC Testing-Inflatable Frames for RF Shielded Enclosures!

Innovating EMC Testing, Inflatable Frames for RF Shielded Enclosures. In the realm of EMC testing where precision is paramount, inflatable frames for RF Shielded Enclosures are emerging as game-changers. These structures, utilizing flexible, airtight materials, are revolutionizing testing environments with their scalability and portability. Created using durable materials and reinforced with strong fibers, inflatable frames provide the skeleton for RF Shielded enclosures. The frame supports RF Shielded Enclosures fabricated incorporating conductive fabrics containing copper...

28May

Megastructures- RF Shielded Enclosures for Giants!

Megastructures- RF Shielded Enclosures for Giants! You've heard me say it before, VTT will design and assemble the RF Shielded Enclosure to fit your specific needs. We start by meeting with our customer, learning their requirements. Next, we design the enclosure, working with the customer to create the enclosure that will meet their specific needs. Options include: Shielding Effectiveness (SE), lighting, environmental control (Air Conditioning and/or ventilation), doors/lift walls, input/output, RF Filtered Power. Once we determine the customer's needs, we...

06May

Pre-Compliance EMC Testing-Producing Great Products!

Pre-Compliance EMC Testing-Producing Great Products! In the bustling world of electronic device development, ensuring that your products comply with electromagnetic compatibility (EMC) standards is crucial. Electronic products can't go to market until they pass until they pass final compliance testing. Achieving EMC compliance is a daunting task that is fraught with potential pitfalls and costly setbacks. Pre-Compliance EMC testing is a proactive approach that offers many advantages to manufacturers who are looking to streamline their product...

30Apr

Elevating your Brand-the Power of Quality!

Elevating your Brand-the Power of Quality! In the realm of product development, the integration of quality components is paramount. Just as a virtuoso musician relies on fine instruments to create masterpieces, integrating superior components elevates product performance and reliability, thus shaping the customer experience. Here's why prioritizing quality components is crucial: Enhanced performance: Quality components ensure optimal functionality, delivering seamless experiences that exceed customer expectations and bolster brand reputation. Durability and Longevity: Superior components are synonymous with durability, minimizing premature failures and...

22Apr

Pre-Compliance EMC Testing-Powerful Tool!

Pre-Compliance EMC Testing-Powerful Tool! Time is of the essence in product development, as speed to market can make or break a company's success. Any delays in the developmental process can have significant consequences. One often overlooked aspect of product development is Pre-Compliance electromagnetic compatibility (EMC) testing. This testing, when integrated into the early stages of development, can yield substantial benefits. EMC testing involves assessing a product's ability to operate without interfering with other devices or being susceptible to interference itself. ...

02Apr