A Concise Guide to Pre-Compliance EMC Testing!

A Concise Guide to Pre-Compliance EMC Testing! Pre-Compliance EMC testing is emerging as a critical step in product development. Electronic devices must meet electromagnetic compatibility (EMC) standards prior to marketing. Here’s a concise guide, distilling the process to its most vital steps:

- Understanding EMC and Standards-Begin by understanding EMC fundamentals and pinpointing relevant regulatory standards such as FCC or CE marking that are apply to your product.

- Select the Applicable Standards-Identify and focus on the specific standards your product must meet, and tailor your testing strategy accordingly.

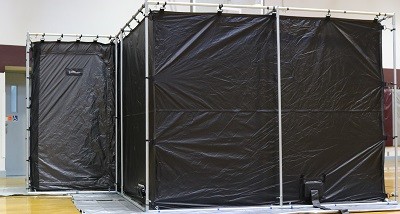

- Setting up the Testing Environment-Establish a shielded testing environment RF Shielded Enclosure that meets industry standards, equipping it with necessary tools or partner with an accredited testing facility.

- Preliminary Assessments-Review your product’s design thoroughly, including schematics and layout to identify potential EMI sources and pathways.

- Developing Test Plans-Create detailed test plans, covering radiated emissions, conducted emissions, radiated immunity, and conducted immunity, addressing key EMC aspects.

- Radiated Emissions Testing-Utilize your testing chamber to measure unintentional electromagnetic energy release from your device across various frequency ranges.

- Conducted Emissions Testing-Assess unwanted electromagnetic energy conducted through power and signal lines to ensure your product doesn’t introduce excessive noise.

- Radiated Immunity Testing-Expose your device to various radiated fields, evaluating its resilience against external electromagnetic interference.

- Conducted Immunity Testing-Evaluate your device’s immunity to disturbances, introducing them through power and signal lines to assure reliable operation.

- Analysis and Refinement-Thoroughly analyze test results, identifying shortcomings and refine the product’s design through additional testing rounds.

- Documentation and Certification-Compile and document test reports and design modifications. These are necessary for final Certification. Following these steps allows proactive addressing of EMC issues while aligning you with regulatory standards.

V Technical Textiles, Inc.

www.vtechtextiles.com

info@vtechtextiles.com

(315)-597-1674 Phone

(315)-597-6687 FAX

Experience, Research, Dedication, and Commitment

Leave a Reply