EMC Compliance Testing-“Prep” your Product!

EMC Compliance Testing-“Prep” your Product! EMC Compliance testing is often the final obstacle to product marketing. It’s important to prepare your product for this test! Best Practice for Final EMC Compliance Testing is Pre-Compliance EMC Testing! Pre-Compliance Testing at your own facility beginning early in development is great preparation! This allows identification and mitigation of problems during every step of development. Backtracking to find problems is time consuming and frustrating! Products developed in this way will likely pass Final Compliance Testing easily. The process is analogous to a school student studying for a test. Slow, steady preparation is the right way to go!

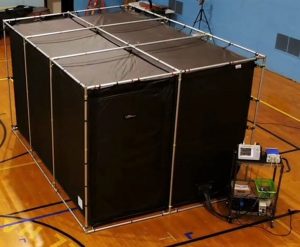

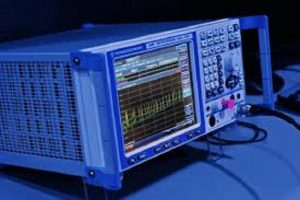

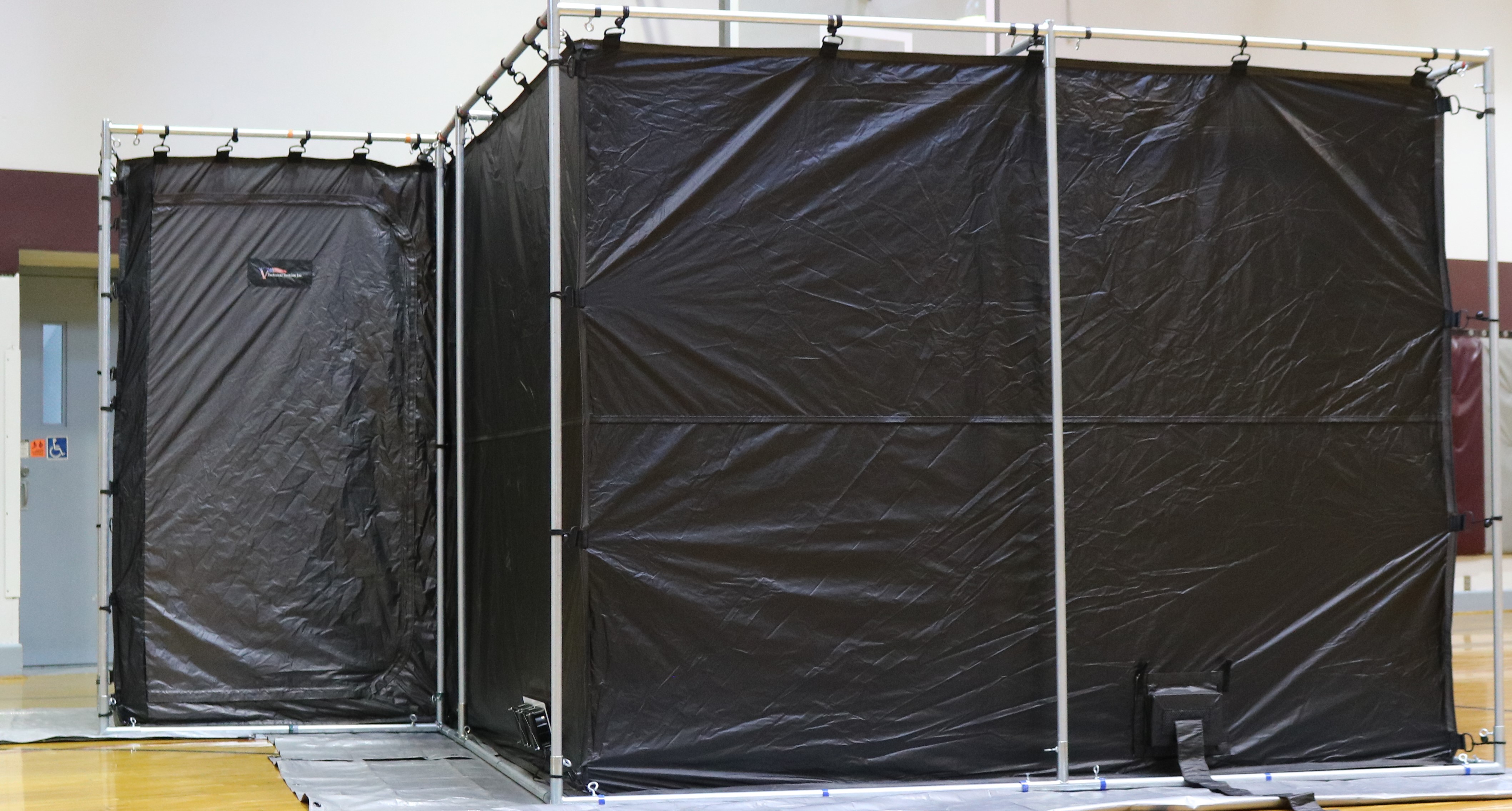

EMC Compliance Testing-“Prep” your Product! Pre-Compliance Testing saves time and money in development. Time spent at the testing center and money to have the testing done! Pre-Compliance EMC Testing requires an RF Shielded Testing Enclosure. This enclosure provides the low ambient environment required for EMC Testing. The conductive metal textiles that they are fabricated with prevent electromagnetic fields from entering the enclosure. The equipment needed for Emissions Testing is: EMI Antenna, Spectrum analyzer, pre-compliance measurement software, and a pre-amplifier. Susceptibility Testing requires: Spectrum analyzer, pre-compliance measurement software, LISN, and a Limiter. Immunity Testing requires: Signal Generator, near field probes, and a radio.

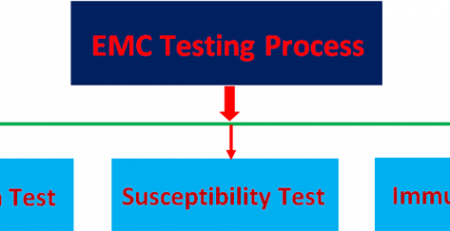

EMC Compliance Testing-“Prep” your Product! There are three tests that are performed on the Device Under Testing (DUT). Radiated Emissions, Conductive Emissions, and Immunity:

- Radiated Emissions-This test determines if the DUT is emitting radiation above the acceptable level. Failure means a Shielding Solution must be engineered to eliminate the excessive emission.

- Conductive Emissions-This test determines if DUT electronic connections are radiating interference above accepted level. Failure means RF filtered lines or other shielding must be used to eliminate these emissions.

- Immunity Testing-This test determines if the device functions optimally in the electromagnetic environment it operates in. Failure indicates the need for a Shielding Solution to allow optimal performance.

EMC Compliance Testing-“Prep” your Product! If you’ve done Pre-Compliance EMC Testing during development, your device should pass with flying colors! V Technical Textiles, Inc. can design and fabricate an RF Shielded Enclosure for your Pre Compliance EMC Testing needs. We also supply shielding materials or assist in designing Shielding solutions for your device. Please contact us for ways to “Prep your Product” for Final EMC Testing!

V Technical Textiles, Inc.

www.vtechtextiles.com

info@vtechtextiles.com

(315)-597-1674 Phone

(315)-597-6687 FAX

Experience, Research, Dedication, and Commitment

Leave a Reply