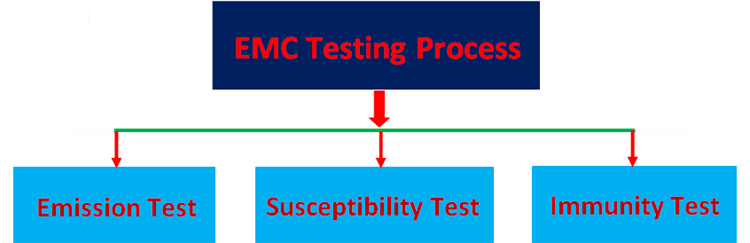

Electromagnetic Compatibility-when devices work smoothly Together!

Electromagnetic Compatibility-when devices work smoothly Together! Devices are like people, they work best when they’re compatible. Electronic devices work best when they don’t interfere with each other. Electronic devices can be interfered with in several ways. They can be “distracted” by RF interference emitted by nearby devices. This distraction is similar to a co-worker who is always talking. The background “noise” keeps work quality below its potential best. Devices that can be “distracted” are called “susceptible”. The answer to susceptibility to “RF noise”, is a Shielding Solution. Shielding involves “blocking” the interfering noise from reaching the device. This is like putting earplugs in the ears of a worker who is bothered by noise. Electromagnetic Shielding often involves the use of conductive metalized textiles. These textiles act as a bulletproof vest, blocking the RF interference.

Electromagnetic Compatibility-when devices work smoothly Together! Sometimes a device emits RFI that causes malfunction of nearby devices. The device that emits RFI above acceptable levels is an “emitter”. The answer to an “emitter”, is to stop the emissions. Once again, a shielding solution is applied, covering the emitter. This is like putting a gag on a person that won’t stop talking. Conductive metalized textiles are used to stop/block the emission. Most electronic devices today are designed to be compact. Engineers love these textiles, because they’re lightweight, flexible, and adaptable. All of these characteristics make them great in engineering design!

Electromagnetic Compatibility-when devices work smoothly Together! Devices can be affected by “various types of electromagnetic phenomena”. These can be conducted, radiated, magnetic field induced, surges, voltage drop, electrostatic in nature. A device is considered “immune” when it is not affected by these phenomena. Use of conductive textiles or filters in connected lines yields immunity.

Listed above the common causes of electromagnetic “incompatibility”. Most compatibility issues can be resolved using proper shielding techniques. Catching potential EMC issues during development is easily done in house. Pre-Compliance EMC Testing during development saves time and money. A sampler of our conductive textiles can be purchased at our shopping site. V Technical Textiles, Inc. has the world’s largest standing inventory of conductive textiles. Contact us for help in selecting the right conductive textile, testing supplies, and Shielding Solutions for you!

V Technical Textiles, Inc.

www.vtechtextiles.com

info@vtechtextiles.com

(315)-597-1674 Phone

(315)-597-6687 FAX

Experience, Research, Dedication, and Commitment

Leave a Reply