Efficient Best Practice- Frequent EMC Developmental Testing!

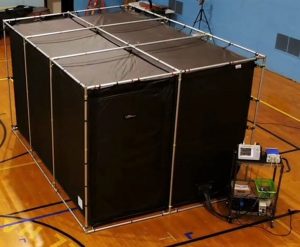

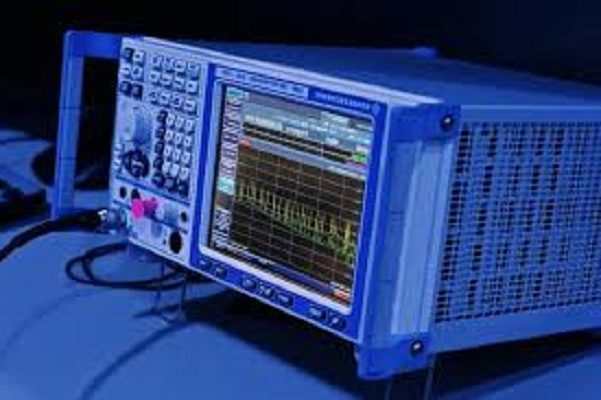

Efficient Best Practice-Frequent EMC Developmental Testing! Frequent EMC developmental testing sounds like a lot of work. It also sounds like a waste of precious time. The truth is doing the testing early and often saves a lot of time! “Backtracking” to mitigate/diagnose problems is the real waste of time. Backtracking means “to retrace one’s steps” or to “pursue, trace, and monitor”. I call it “going back to the drawing board”! Talk about time consuming, that’s the definition of backtracking! Pre-Compliance EMC testing is of part efficient device design strategy. Pre-Compliance EMC testing can be done in your own facility. It requires a low ambient RF testing chamber and equipment. VTT manufactures RF Shielded EMC Testing Enclosures. These enclosures are lightweight, portable, and easy to assemble.

This brings the “test lab” to your product. You’ve already saved travel and lab time and expenses. Now comes the Pre-Compliance EMC testing.

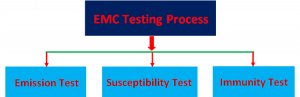

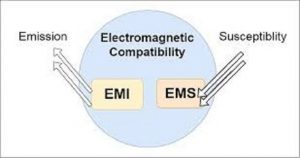

Efficient Best Practice-Frequent EMC Developmental Testing! EMC Testing consists of three tests. Emissions Testing, the Device Under Testing (DUT) is placed in the enclosure. The device is then run in the chamber. Emissions from the device are monitored and classified. If the emissions fall in the acceptable range the device passes. Emissions are outside of the acceptable range make the device an “emitter”. Now is the time to correct that problem. Susceptibility Testing determines if the DUT is susceptible to acceptable levels of RFI/EMI. The device is run in an environment at the highest acceptable level of RFI/EMI. If the device is not performing at its best level, the device is “susceptible”. Again, this problem should be dealt with before further development. Immunity Testing measures the device’s ability to function during exposure to electromagnetic phenomena. It is almost the opposite of the Emissions Testing. If the device is adversely affected by these phenomena, it must be “immunized” against them. When the device has passed these three tests, development can proceed.

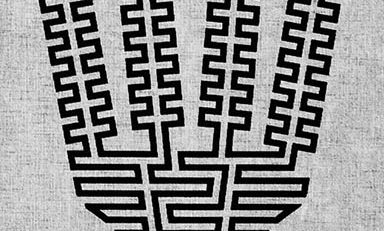

Efficient Best Practice-Frequent EMC Developmental Testing! The problems noted in each of the tests listed above can usually be corrected by Shielding Solutions. Conductive Textiles are excellent solutions to EMC problems. They block EMI/RFI from getting to or leaving the device, solving emissions and susceptibility issues. Their lightweight, thinness, and flexibility make them “heavyweights” in the shielding arena. Contact us to begin performing your own Pre-Compliance EMC Developmental testing at your site!

V Technical Textiles, Inc.

www.vtechtextiles.com

info@vtechtextiles.com

(315)-597-1674 Phone

(315)-597-6687 FAX

Experience, Research, Dedication, and Commitment

Leave a Reply