Electromagnetic Compatibility-when Components get Along!

Electromagnetic Compatibility-when Components get Along! Electromagnetic Compatibility is when components of a device get along. In new devices, the components must work together in a shared electromagnetic environment. If the devices aren’t compatible, the device performance suffers. A device should be like a team, many parts working toward one goal. Successful teams are assembled of people who work toward a goal smoothly. Each player executes his job without holding the team back. Similarly, one teammate can adversely affect the function of the whole team.

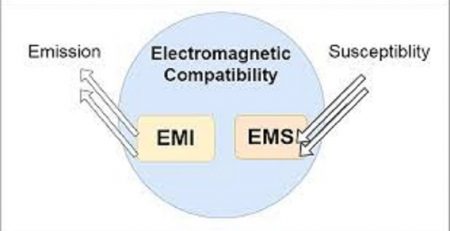

Electromagnetic Compatibility-when Components get Along! Continuing the team analogy in electronic devices, the culprit is likely emitting or susceptible to RFI/EMI. If the component is emitting excessive RFI/EMI into the device, it is called an emitter. If a component’s performance is adversely affected by allowed RFI/EMI, it is “susceptible”. In device development, typically EMC Pre-Compliance testing is done frequently. Pre-Compliance EMC testing identifies potential RFI/EMI issues. This testing allows these issues to be corrected during development. This stepwise best practice product development saves time and money during development.

Electromagnetic Compatibility-when Components get Along! Pre-Compliance EMC Testing consists of testing each component for emissions, susceptibility, and immunity. Emissions testing makes sure that the component is within standard acceptable emissions. Susceptibility testing determines if the component is susceptible to acceptable levels of RFI/EMI. Immunity testing determines if the device is immune to standard emissions and other electromagnetic phenomena. Treatment of the Emissions, Susceptibility, and immunity issues usually involves shielding. An “emitter” is shielded by covering it with a shielding material, preventing unacceptable emissions. If a device is “susceptible” to acceptable levels of RFI/EMI, it is usually covered with a shielding material. This stops RFI/EMI from reaching the device, allowing normal function. A device that isn’t immune to electromagnetic phenomena is also shielded. This shielding can be filters in the lines connecting the device to other devices. The best shielding materials are usually conductive textiles. These textiles block RFI/EMI from crossing their boundary using the “Faraday Cage Effect” first noted by Michael Faraday in 1836. These textiles are thin, lightweight, and adaptable, making them excellent shielding materials.

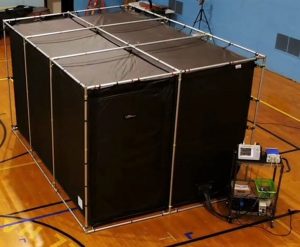

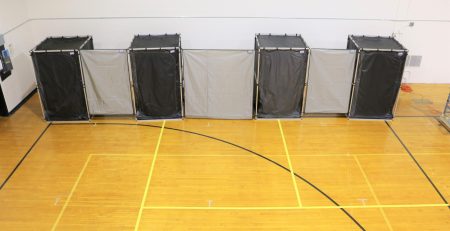

Electromagnetic Compatibility-when Components get Along! Pre-Compliance EMC testing is usually done in RF Shielded Testing Enclosures. These enclosures assure the low ambient RF environment necessary for testing. The device is run in the testing enclosure and monitored for unacceptable emissions. The device is also run in the chamber and challenged with RFI/EMI up to standard levels to assure “immunity” to acceptable levels of RFI/EMI. The shielding solutions mentioned above are applied and the device is retested. Once the device passes Pre-Compliance EMC Testing, it will usually pass the Final Compliance EMC Testing at a registered facility and will be approved for sale.

V Technical Textiles, Inc. has the world’s largest selection of conductive textiles used in shielding applications. See and feel these unique fabrics by purchasing a fabric swatch catalog at our shopping site! We also fabricate the RF Shielded EMC Testing enclosures mentioned above. These enclosures are custom made to meet the needs of our customers. Contact us to learn about Pre-Compliance EMC Testing, RF Shielded EMC Testing Enclosures, and conductive textiles used in the shielding applications listed above!

V Technical Textiles, Inc.

www.vtechtextiles.com

info@vtechtextiles.com

(315)-597-1674 Phone

(315)-597-6687 FAX

Experience, Research, Dedication, and Commitment

Leave a Reply