Size Problem? Large or Small, VTT can Help with your EMI Testing Needs!

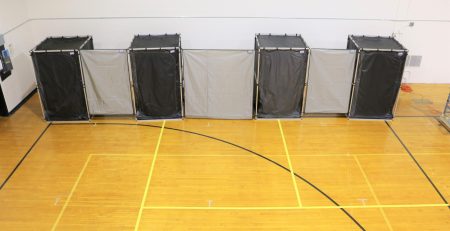

Electronic devices come in many sizes, whether your device is the size of a cubesat, an automobile, military vehicle, or a spacecraft, V Technical Textiles can help you with your EMI Testing needs by providing you with one of our portable RF Shielded Testing Enclosures, specially designed for your testing needs.

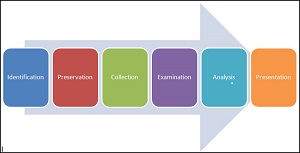

EMI testing follows two basic tests that determine if a device is fit to work in an environment with several types of electronic devices in it. The first test is the “emission test” that determines if the Device Under Testing (DUT) is emitting RFI into the shared environment that will affect the other devices’ performance adversely, like the person at the office that keeps interrupting your train of thought so you can’t get your work done efficiently. If the device is found to be emitting RFI at a higher amount than is allowed by the standards in place, the device must be “shielded” to prevent the emission of this interference before it is determined to “meet the standards” and be certified as “compliant” after a final test at a certified testing facility.

The second test is the “susceptibility test” which determines if the DUT is “susceptible” to RFI that will be present in the shared environment, making it become “distracted” by this interference and incapable of functioning up to its best standards, like the employee that gets hooked into a conversation with a co-worker while working and doesn’t complete the work assignment successfully. If the DUT is deemed to be susceptible to RFI that will be present in its working space, shielding solutions must be applied to “mitigate” the susceptibility, acting like ” sound canceling earplugs” making the device no longer affected by the “noise” in the shared environment and is able to work up to its design specifications.

The point of being able to do this pre-compliance testing at the point of manufacture is to allow the adjustment of your device when you detect that it needs it, taking care of EMI issues before taking the device to a registered testing facility and finding out that the device fails to comply with mandatory standards and has to be taken back to your facility for mitigation of the issues and returning for another test. The travel time and test expenses saved are well worth doing the testing and mitigation in advance of the final compliance test….like the time spent by a good student preparing for the final examination knowing that the test should go smoothly due to good preparation.

V Technical Textiles, Inc. is the world leader in the fabrication of these enclosures and supply them to many different industries. These enclosures are custom made to your specific needs, including: ventilation, lighting, power, interfaces for input and output for testing devices, shielded curtains, and levels of Shielding Effectiveness!

Contact us for help with registration and any questions you may have about RF Shielded Enclosures and Shielding Solutions!

V Technical Textiles, Inc.

www.vtechtextiles.com

info@vtechtextiles.com

(315)-597-1674 PHONE

(315)-597-6687 FAX

Leave a Reply