RF Emissions and RF Susceptibility, EMC Test Devices Early and Often in Development!

RF Emissions and RF Susceptibility, EMC test devices early and often in development!

- RF Emissions– every electronic device emits RF waves during function. Some of these RF waves are acceptable in the environment. Some of them can adversely affect the function of other nearby devices. The RF Emissions should be checked early and often during development. This process prevents the need to change the device design completely late in the game.

- RF Susceptibility– If RF waves in the area decrease the function of the device, the device is susceptible. An RF Shielding Solution is needed to shield the device from these waves. This kind of solution often involves thin metalized conductive textiles. These textiles block the RF waves from the device, allowing optimal function.

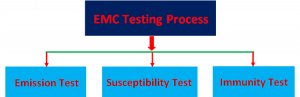

RF Emissions and RF Susceptibility, EMC Testing helps detect and identify these problems.

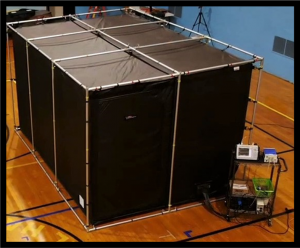

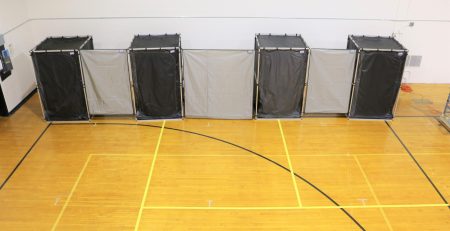

EMC Testing is done inside of an RF Shielded Enclosure, made of metalized conductive textiles. These enclosures work on the Faraday Principle developed by Michael Faraday in 1836. They ensure an “ambient free” environment ideal for EMC testing.

V Technical Textiles, Inc.’s RF Shielded Testing Enclosures: Single Room, Enclosure with Foyer, and Benchtop Enclosure.

- RF Emissions Testing– Involves running the Device Under Testing (DUT) inside the enclosure. The RF waves emitted by the device are evaluated to see if they are within the acceptable standards. If the emissions are acceptable, development can proceed. If the emissions are greater than the limit, a Shielding Solution must be applied and the device retested. This process is repeated until device emissions are within acceptable Standards.

- RF Susceptibility Testing– Involves running the DUT inside the enclosure. The device is then exposed to RF radiation up to and above the acceptable standards. If the device does not run optimally in the acceptable range, a Shielding Solution must be applied and the device retested until it runs optimally in the acceptable RF range.

RF Emissions and RF Susceptibility, eliminate them early in device development.

Though the EMC Pre-Compliance testing along the way seems tedious, it will save time and money in the overall development of the device. No matter what sector you work in: Automotive, Aerospace, 5G, or Military, this testing is important! It will also make final compliance testing a “one time” event. That will certainly save you time and money at the testing center!

V Technical Textiles, Inc.’s RF Shielded EMC Testing Enclosures are portable and storable. You can take the enclosure to the device for testing. When not testing, the enclosure can be taken down and stored, saving you space! Though our enclosures come in several standard sizes, most of them are custom-made to our customer’s needs. Contact us today and find out more about how our RF Shielded EMC Testing Enclosures can work for you!

V Technical Textiles, Inc.

www.vtechtexiles.com

info@vtechtextiles.com

(315)-597-1674 Phone

(315)-597-6687 FAX

EMC Testing using an RF Shielded Testing Enclosure at your Facility saves Time and Money during Development!

Leave a Reply