EMI/RFI spell Trouble, VTT offers Solutions!

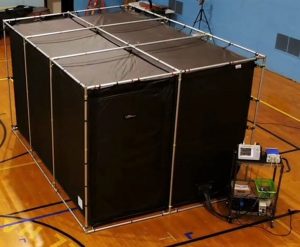

EMI/RFI spell Trouble, VTT offers Solutions! An electronic device can’t be marketed until it is compliant with applicable EMC Standards. Each device has to pass EMC Final Compliance Testing before it can be marketed. Testing is rigorous, device development is crucial in preparation for it. Pre-Compliance testing, starting upon product development is the best way to prepare for the Final Compliance Testing. Pre-Compliance testing is best done “early and often” in your own facility. This development method saves time and money by eliminating expensive “back tracking” to correct multiple problems. RF Shielded Enclosures provide the ideal low ambient testing environment for Pre-Compliance Testing. VTT can fabricate a custom enclosure to test your product. These are not “one solution fits all” enclosures! We design and construct them to your testing needs!

RF Shielded EMC Testing Enclosure

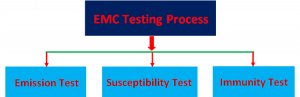

Each component of the device is tested at least three ways:

- Emission Testing– The device is run inside a testing chamber to see what type of EMI/RFI it is emitting. If the device emits EMI/RFI above the acceptable limits, it is classified an “emitter”. This situation must be corrected, usually with a Shielding Solution.

- Susceptibility Testing-The device is tested to see if it is susceptible to “conducted emissions”. These are emissions from devices connected to the device under testing. The correction is usually installing filters at device interfacing points.

- Immunity Testing– The device is tested for immunity to interference from other components operating in its environment. If the device operates optimally in its environment, it is “immune” to interference. If the device malfunctions, the situation must be corrected. The correction usually involves a Shielding Solution.

EMI/RFI spell Trouble, VTT offers Solutions. Every electronic device emits an electromagnetic field. All devices in the shared electromagnetic environment must operate properly simultaneously. Excessive EMI/RFI emission by one device can interfere with the operations of others. The device emitting the offending interference must be shielded, reducing the emission to applicable standards. Shielding is like blanketing the device “containing” the offending emissions.

The opposite situation can exist, meaning a device that can’t operate in a standard environment. The device is “susceptible” to acceptable ambient levels of RFI/EMI. This time the shielding solution works in the opposite way. The “susceptible device” must be shielded from its environment so it can work properly. In this case, the shielding material covers the device, blocking EMI/RFI from affecting the device. In this way, a “susceptible” device can be “immunized” to the standard environment by the Shielding Solution.

The Shielding Solution in both situations can often be a metalized conductive fabric. Engineers love these materials due to their light weight and flexibility. These properties allow the shielding solution to take up minimal space, keeping the device small and lightweight. The conductive fabrics are available in a wide range of Shielding Effectiveness (SE). The fabric can be matched to the frequency required to be shielded. V Technical Textiles, Inc. has the world’s largest selection of quality conductive metalized textiles available for your shielding needs!

Please contact us if you would like to find out more about Pre-Compliance EMC Testing or available Shielding solutions for RFI/EMI interference issues.

V Technical Textiles, Inc.

www.vtechtextiles.com

info@vtechtextiles.com

(315)-597-1674 Phone

(315)-597-6687 FAX

Experience, Research, Dedication, and Commitment!

Leave a Reply