Shielding RF/EMI allows Electronic Teamwork!

Shielding RF/EMI allows Electronic Teamwork! Electronic components consist of several electronic devices working together toward a common result. All electronic devices create electromagnetic fields. Electromagnetic fields can be the source of “noise” that can affect the function of another nearby device or devices in the component. Noise produces a “toxic effect” on the shared electronic environment of the component, making it function below its capability. In order for the devices to be “compatible” with each other, there must be standards for the electromagnetic emissions of devices. Standards that determine the maximum frequency characteristics of the emanations allowable for the devices to be “electromagnetically compatible”.

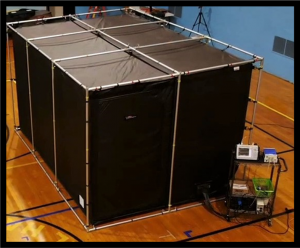

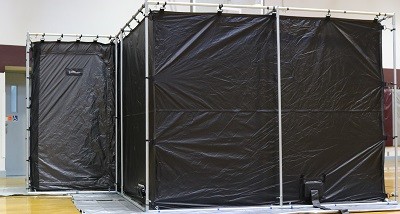

Shielding RF/EMI allows Electronic Teamwork! Every electronic device must pass EMC Compliance Testing prior to being marketed. EMC Compliance Testing consists of three exacting tests, performed in a low ambient RF/EMI environment such as an RF Shielded Testing Enclosure:

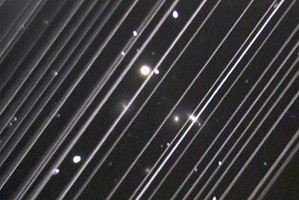

- Emissions Testing measures the type and quantity of RF/EMI radiation the Device Under Testing (DUT) emits. Devices emitting more RF/EMI than the standards are classified as “emitters”. Unacceptable emissions must be reduced to standard. A “Shielding Solution” is applied to the device, reducing the level of RF/EMI radiation the device emits. Shielding Solutions often involve the wrapping the device with a metalized conductive textile “blanket”. Conductive textiles block the release of the excessive RF/EMI radiation the device emits, making it compliant with standards.

- Susceptibility Testing determines whether the device is “susceptible” or adversely affected by RF/EMI present in an acceptable standard electromagnetic environment for the device. If the device is “susceptible”, a “Shielding Solution” is applied using a conductive textile blanket for the device, blocking the “offending standard frequency” from reaching the device and allowing the device to perform optimally.

- Immunity Testing determines the ability of the device is to withstand “electromagnetic phenomena”. These are typically magnetic fields, voltage drop, power surges, conducted and radiated interference, ElectroStatic Discharge (ESD), Electrical Fast Transient (EFT) load. These issues are often mitigated with filtered power lines and other shielding methods.

Shielding RF/EMI allows Electronic Teamwork! As illustrated above, most EMC issues can be eliminated by proper RF/EMI Shielding Solutions. V Technical Textiles, Inc. has the world’s largest inventory of frequency specific metalized conductive textiles, designed to block the specific frequencies that are causing electromagnetic compatibility issues. Pre-Compliance EMC Testing during product development can decrease the hassle of having to “work backwards” to correct the shielding issues at the end of development. Contact V Technical Textiles, Inc. for your RF/EMI Shielding needs and RF Shielded EMC Testing Enclosures to help simplify product development!

V Technical Textiles, Inc.

www.vtechtextiles.com

info@vtechtextiles.com

(315)-597-1674 Phone

(315)-597-6687 FAX

Experience, Research, Dedication, and Commitment

Comment (1)

[…] Textiles-What are their Uses? Metalized textiles were first used in various Shielding Applications. I can remember when an automobile FM radio mainly played static! Metalized textiles played a […]