RF/EMI Shielding-the Key to EMC!

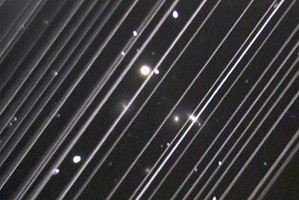

RF/EMI Shielding-the Key to EMC! Electromagnetic Compatibility Standards must be met prior to marketing devices. The device must perform well in a shared electromagnetic environment. It must not disrupt the performance of other nearby devices. It must not be disrupted by its environmental coworkers. The “potential disruption” is caused by RF/EMI outside of acceptable standards. In the US, the FCC determines these standards. In Canada, Industry Canada determines the standards. Europe requires the “CE” mark that represents compliance. Every country in the world regulates EMC of products marketed within its borders. EMC testing can take up to two weeks to complete. This does NOT include the lead time from scheduling to testing! The cost of testing is steep, but necessary for certification. Failure of EMC Testing can result in a costly redesign process. Failure also delays the launch date of the device. This is an important test to pass on the first try!

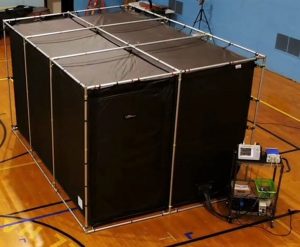

RF/EMI Shielding-the Key to EMC! To achieve EMC, RF/EMI must be kept at acceptable levels. The key to this is RF/EMI Shielding. Proper shielding can eliminate RF/EMI in the device’s environment. EMC Pre-Compliance Testing should be done early and often during product development. This process will keep costly redesigns to a minimum. I mentioned that Final Compliance Testing can be expensive in both money and time. Pre-Compliance EMC Testing can be accomplished in your own facility at your convenience. It requires an RF Shielded EMC Testing Enclosure and several instruments. The ability to do this testing will save precious time and money in product development!

RF/EMI Shielding-the Key to EMC! Pre-Compliance Testing consists of three steps:

- Emissions Testing– The device is tested to see if it is emitting unacceptable RF/EMI. If it is, the device is an “emitter”. An RF/EMI Shielding Solution can be applied to block these emissions.

- Susceptibility Testing– The device is tested to see if acceptable RF/EMI affects its operation. If it does, an RF/Shielding Solution can block RF/EMI from effecting the device.

- Immunity Testing– The device is tested for effects from various electromagnetic phenomena. Filters and Shielding can put a stop to this issue.

RF/EMI Shielding-the Key to EMC! As you can see, proper RF/EMI Shielding can correct EMC obstacles. Conductive metalized textiles are excellent shielding solutions for RF/EMI issues. V Technical Textiles, Inc. has the world’s largest standing inventory of these amazing textiles. These lightweight, adaptable, and flexible textiles are an engineer’s dream come true for shielding solutions. Contact us for help in selecting the conductive textile that is the “Key to your EMC!”

V Technical Textiles, Inc.

www.vtechtextiles.com

info@vtechtextiles.com

(315)-597-1674 Phone

(315)-597-6687 FAX

Experience, Research, Dedication, and Commitment

Leave a Reply