Robots are Good Workers, but can Make a lot of Noise in the Testing Room. An Absorber Sleeve can Quiet things Down!

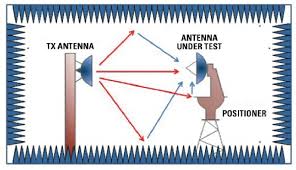

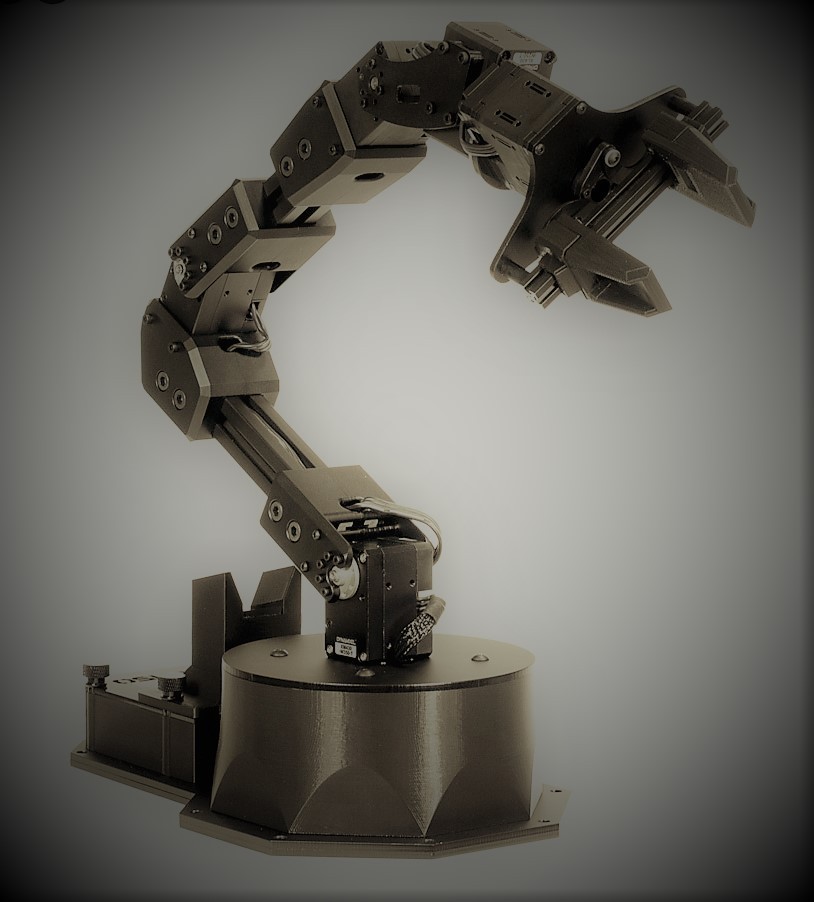

Antenna manufacturers make antennas for many uses. The end user of each antenna needs to know the characteristics of the antennas to make sure that they are performing to their specifications. The “characteristics” of an antenna’s transmission and reception of signals are called the antenna’s patterns. These pattern measurements must be VERY precise and done with the antenna in many different positions during testing. In order to make sure that the position of the antenna is correct, robotic arms are used to automate the testing, with the two robotic arms controlling the position of the two antennas involved in the test (one transmitting and the other receiving) during testing in order to make the results of the testing repeatable.

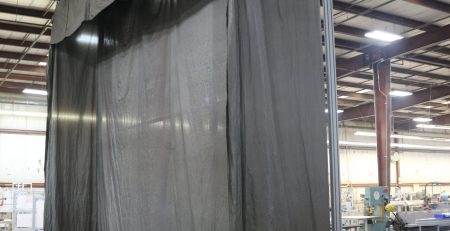

The problem is that any metal in the testing enclosure environment causes reflection of radio waves. With two metallic robot arms in the anechoic testing room, reflections from the metallic surfaces of the robot arms present in the room will cause errors in measurements resulting in inaccurate antenna patterns or performance.

Better testing results for the Antenna Under Testing (AUT) would be achieved by coating the robotic arms with an absorber of RF waves. This is challenging, as the robotic arms move and the absorber material is often brittle. When the robot arm flexes in order to make the changes of position of the antenna during the test, it brings the problem of flexing a brittle substance, the absorber, to bear. V Technical Textiles, Inc. is developing an absorber sleeve with a conductive fabric backplane to eliminate this reflection problem during testing and give better determinations of antenna patterns.

V Technical Textiles, Inc.

www.vtechtextiles.com

info@vtechtextiles.com

(315)-597-1674 PHONE

(315)-597-6687 FAX

Leave a Reply