Pre-Compliance Testing is Important, Prepare your Product for the Final!

Pre-Compliance Testing is important, prepare your Product for the Final! I’m not talking about school here. Manufacturers of electronic devices know exactly what I’m talking about. In order for an electronic device to be marketed, it must pass Final Compliance Testing on RFI susceptibility and RFI emission standards. These standards regulate how much RFI affects the device, and how much RFI the device emits. The device must pass these rigorous Final Compliance Tests at approved testing centers in order to be marketed. The Certified Testing Centers are busy, and the wait time for a Final Compliance Test appointment can be long. The cost of the test is high, meaning that repeating the test for a failure costs the developer additional money and time before the product can come to market.

Smart companies perform Pre-Compliance Testing of their devices during development to make sure that their device is ready for the Final Compliance Test before scheduling it. This means checking for Susceptibility Issues (meaning that your device may not work well in due to RF Incompatibility in the device’s operating environment) and Emission Issues (meaning the device is emitting unacceptable RF Interference that will cause other nearby components to malfunction). These Pre-Compliance Tests during development of the device allow the RF Interference issues to be mitigated as they are discovered during development and prior to Final Compliance Testing.

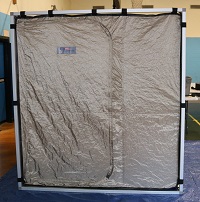

Pre-Compliance Testing is Important, Prepare you Product for the Final. The Pre-Compliance Testing is done at your facility in an ambient-free environment called an RF Shielded Enclosure, consisting of two tests:

- The Emission Test is performed by operating the Device Under Testing (DUT) in the ambient free enclosure and monitoring the DUT‘s RF Emission to make sure that the RF that the DUT emits is at or below the acceptable level.

- The Immunity Test is performed by operating the DUT in the RF Shielded Enclosure and “painting” the DUT with RF Interference up to and above the acceptable level to make sure that the device will be able to perform optimally in the environment that it will be operating in.

Failure of either of these Pre-Compliance Tests allows the DUT to have the problems mitigated by a proper shielding solution to modify the device so it conforms to the Required Compliance Standards. Think of Pre-Compliance Testing in your own facility as “preparing the device for a crucial “Final Exam” at the Registered Testing Facility. It’s far easier and less expensive to pass the test if the device is well-prepared during development!

V Technical Textiles, Inc. is the world’s leader in production of Portable RF Shielded Enclosures. These enclosures help manufacturers to get their products to the market by allowing Pre-Compliance Testing to be done at their own facilities, making the required Final Compliance Test easy, as the problems can be addressed as they arise in the development process and prior to Final Compliance Testing! Though we have standard enclosures available, most of our RF Shielded Testing Enclosures are custom designed to provide the size, specifications, and data Input/Output Options specifically for your needs. Please Contact us for help in designing your RF Shielded Enclosure!

V Technical Textiles, Inc.

www.vtechtextiles.com

info@vtechtextiles.com

(315)-597-1674 Phone

(315)-597-6687 FAX

Leave a Reply