13Nov

30Oct

Upcoming Issues and Solutions in EMC!

Upcoming Issues and Solutions in EMC! Electromagnetic Compatibility (EMC) is a crucial consideration in today's increasingly connected world. As the technology continues to evolve, new challenges and issues in EMC will continue to emerge. Here are some of these upcoming issues and potential solutions: IoT and Wireless technologies- The rapid growth of the Internet of Things (IoT) devices and the roll out of 5G networks bring about EMC challenges. In order to address this, manufacturers must improve EMI shielding and...

16Oct

The Remarkable Evolution of EMC!

The Remarkable Evolution of EMC! Electromagnetic Compatibility EMC is a critical field that has evolved significantly from the late 19th and early 20th centuries. In its infancy, EMC was primarily concerned with ensuring that radio communication and early electrical devices could operate without interference. Today, EMC plays a pivotal role in the design and the regulation of electronic systems, their emissions, and their susceptibility to emissions, that define our modern world. In the early 20th century, the advent of radio...

09Oct

RF Shielded Enclosures have many Applications!

RF Shielded Enclosures have many Applications! In our increasingly interconnected world, the need to manage environmental electromagnetic interference grows daily. RF Shielded Enclosures, also known as Faraday Cages, play pivotal role in achieving this objective across several industries. These unique structures are specifically designed to block Radio Frequency (RF) and electromagnetic radiation, serving many purposes. Today, we will delve into the key applications of RF Shielded Enclosures and the industries that depend on them. RF Shielded Enclosures form the cornerstone of...

20Sep

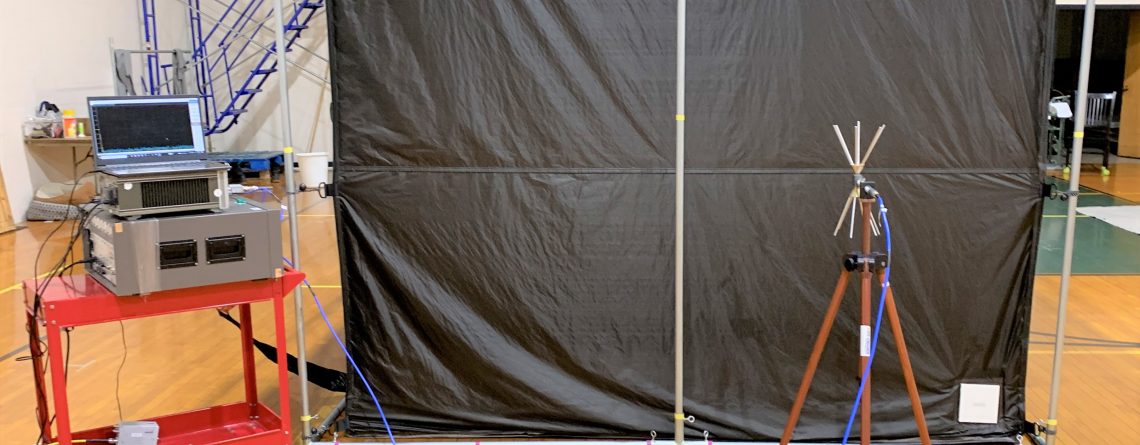

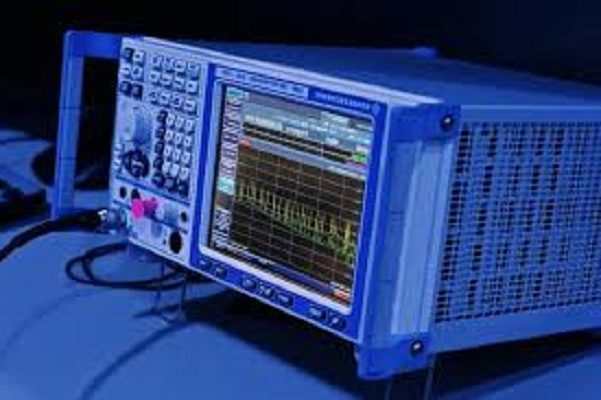

Pre-Compliance EMC Testing-Beneficial!

Pre-Compliance EMC Testing-Beneficial! This preliminary testing offers many benefits that save time and money in getting a product to the market efficiently. Firstly, it allows you to spot potential EMC issues during the design process. This allows you to make adjustments which can eliminate costly redesigns late in the manufacturing process. These adjustments ultimately save the time and money it takes to "backtrack" to find the issues after the product is nearly complete. Streamlining product development time is important in...

19Sep

Metalized Textiles in Healthcare-Versatile!

Metalized Textiles in Healthcare-Versatile! Among the many advancements that are constantly occurring in the medical field, Conductive Metalized Textiles have emerged as versatile and indispensable assets. These textiles, infused or coated with metallic elements, have found many uses in healthcare beyond their well-known shielding properties. Let's look into some of the most common uses of metalized textiles in the medical arena. Radiation protection is a must when medical professionals go into radiology departments. Metalized textile aprons and vests offer a...

12Sep

Conductive Textile’s role in Automotive Innovation!

Conductive Textile's role in Automotive Innovation! Automobiles are becoming increasingly dependent on electronic devices. Where you find electronic devices, you will often find conductive textiles. The initial role for conductive textiles in automobiles was shielding the radio from RFI, allowing the radios to play music clearly. Amazingly, one of the primary applications in the automotive industry is still electromagnetic interference (EMI) and Radio-frequency interference (RFI) shielding. Due to ever the ever-increasing number of electronic components in vehicles, ensuring smooth operation...

06Sep

Pre-Compliance Testing in Electronics Development-Crucial!

Pre-Compliance Testing in Electronics Development-Crucial! In the fast-paced world of electronics, ensuring reliability and compatibility of components is paramount. This is where Pre-Compliance Electromagnetic Compatibility (EMC) testing comes into play. Pre-Compliance testing involves evaluating electronic components for potential electromagnetic interference (EMI) and electromagnetic susceptibility (EMS) issues prior to undergoing formal/final EMC certification. Consider it a valuable checkpoint in the development process , saving time, costs, and enhancing the overall quality of the final product. Pre-Compliance Testing in Electronics Development-Crucial! During Pre-Compliance...

16Aug

Smart Development includes Pre-Compliance Testing!

Smart Development includes Pre-Compliance Testing! During product development, it is smart to consider EMC Pre-Compliance Testing. Every electronic device must pass Final EMC Compliance Testing prior to going to market. Failure of this test means "back to the drawing board" for your product for "tweaking" prior to making it to the market. The quicker the Testing is successfully completed, the faster it can be marketed! Another great reason for testing early and often during development is that Pre-Compliance testing makes...

01Aug